1. What is a DC Motor?

A DC motor is an electrical machine that converts direct current (DC) electrical energy into mechanical energy. It works on the principle that a current-carrying conductor placed in a magnetic field experiences a force. DC motors are widely used in industries, electric vehicles, robotics, and home appliances due to their simple speed control and high starting torque.

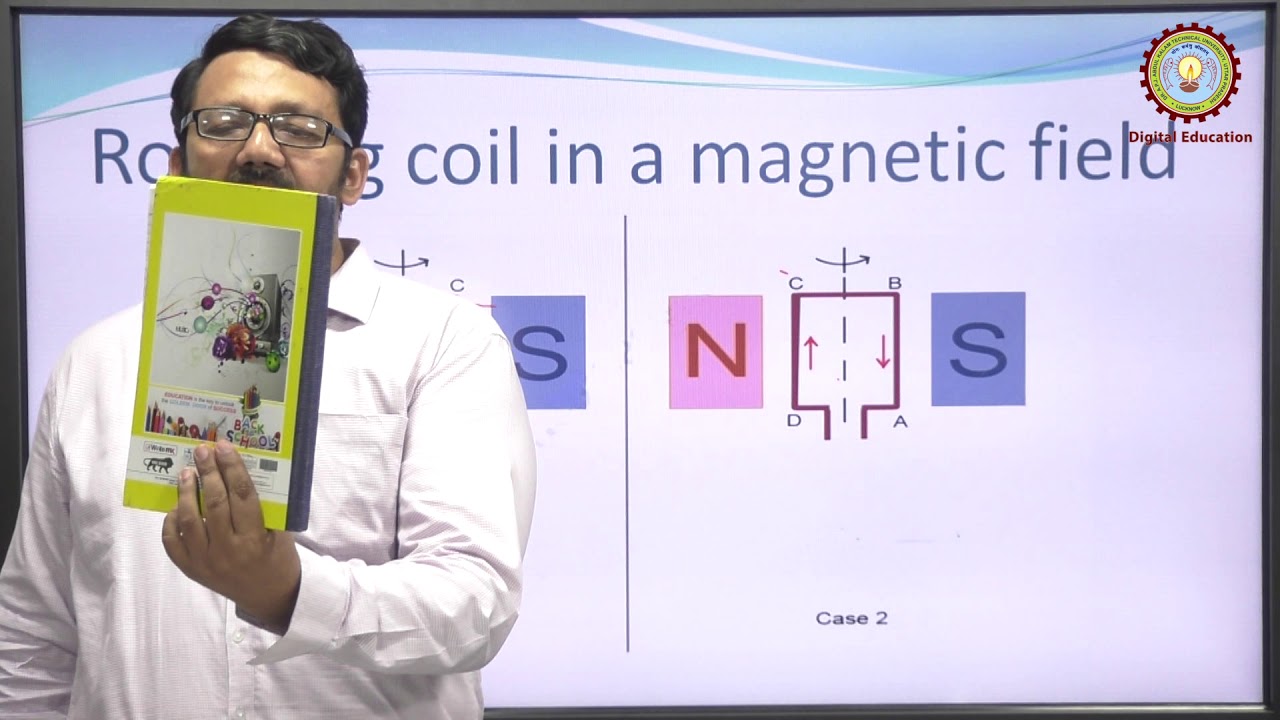

2. How does a DC motor work?

A DC motor operates using the interaction between magnetic fields and electric current. When DC supply is given to the armature winding, current flows through conductors placed in a magnetic field, producing a force according to Fleming’s Left Hand Rule. This force causes the armature to rotate continuously.

3. What are the main parts of a DC motor?

The main parts of a DC motor include the armature, field winding, commutator, brushes, shaft, and yoke. Each component plays a vital role in energy conversion, current supply, and mechanical rotation of the motor.

4. What is the function of a commutator?

The commutator is used to reverse the direction of current in the armature winding after every half rotation. This ensures that the motor continues to rotate in the same direction and provides smooth mechanical output.

5. What are the different types of DC motors?

DC motors are mainly classified into DC shunt motor, DC series motor, and DC compound motor. These types differ based on how the field winding is connected to the armature circuit.

6. What is a DC shunt motor?

In a DC shunt motor, the field winding is connected in parallel with the armature. It provides nearly constant speed under varying load conditions, making it suitable for lathes, fans, and centrifugal pumps.

7. What is a DC series motor?

A DC series motor has its field winding connected in series with the armature. It produces very high starting torque and is commonly used in electric traction systems, cranes, hoists, and elevators.

8. What is a DC compound motor?

A DC compound motor combines the features of both shunt and series motors. It provides good starting torque along with fairly constant speed, making it suitable for heavy-duty industrial applications.

9. What is back EMF in a DC motor?

Back EMF (Electromotive Force) is the voltage generated in the armature due to its rotation in a magnetic field. It opposes the applied voltage and plays a crucial role in regulating current and speed of the motor.

10. Why is back EMF important?

Back EMF limits the armature current and prevents the motor from drawing excessive current during normal operation. It improves efficiency, protects the motor, and ensures stable speed control.

11. How is speed controlled in a DC motor?

DC motor speed can be controlled by varying the armature voltage, field flux, or using PWM (Pulse Width Modulation). Speed control is one of the biggest advantages of DC motors over AC motors.

12. What is torque in a DC motor?

Torque is the rotational force produced by the motor. In a DC motor, torque is directly proportional to the armature current and magnetic flux, making DC motors ideal for high-torque applications.

13. Why do DC motors spark at brushes?

Sparking occurs due to improper brush contact, worn commutator, excessive load, or poor alignment. Regular maintenance helps reduce sparking and improves motor life.

14. What is the efficiency of a DC motor?

The efficiency of a DC motor is the ratio of mechanical output power to electrical input power. High-quality DC motors can achieve efficiencies of 80–90% under proper operating conditions.

15. What are the advantages of DC motors?

DC motors offer excellent speed control, high starting torque, simple control circuits, and reliable performance, making them ideal for automation and electric vehicles.

16. What are the disadvantages of DC motors?

DC motors require regular maintenance due to brushes and commutators, have higher initial cost, and are less suitable for very high-speed applications.

17. Where are DC motors commonly used?

DC motors are used in electric cars, robotics, conveyors, rolling mills, battery-operated devices, CNC machines, and industrial automation systems.

18. Why do DC motors overheat?

Overheating occurs due to overloading, voltage imbalance, poor ventilation, or insulation failure. Continuous overheating can damage motor windings.

19. How can the life of a DC motor be increased?

Regular maintenance, proper lubrication, correct voltage supply, avoiding overload, and timely brush replacement significantly increase DC motor lifespan.

20. Why are DC motors important for engineering students?

DC motors form the foundation of electrical engineering concepts such as torque, EMF, speed control, and energy conversion. They are also important for competitive exams and real-world applications.

.svg)